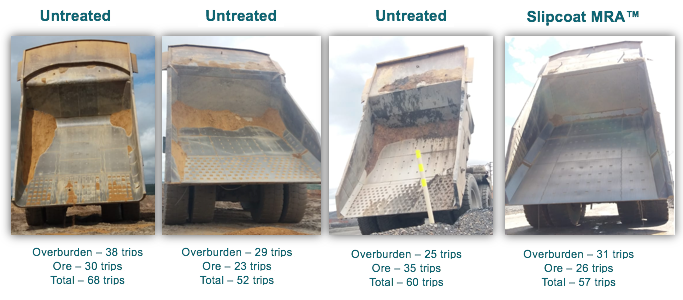

Build-up is an issue at many mining operations worldwide. Global Barrier Services, Inc.’s Slipcoat MRA™ product is able to assist our mining clients by eliminating or greatly reducing this problem, thereby increasing productivity, reducing wear & tear on equipment, reducing maintenance costs and reducing safety concerns related to removing build-up from truck beds and equipment.

Slipcoat MRA™ has been used in both the mining and processing aspect in the following applications:

- Haul Truck Beds/Undercarriages

- Loading Pockets

- Skips

- Excavator/Loader Buckets

- Rail Cars

- Conveyors

- Augers

- Crushing Stations

- Chutes

- Pan Feeders

Some of the benefits of utilizing Slipcoat MRA™ in the mining and railroad industries include:

- Penetrates the metal of truck beds, rail cars and equipment to create a non-stick, protective film

- Requires infrequent application

- Prevents build-up of materials in the truck beds, rail cars and on equipment

- Significantly reduces the amount of clay and mud build-up on vehicle undercarriages

- Reduces the amount of down time required for truck, rail car and equipment cleaning

- Reduces the likelihood of employee injury caused by cleaning of large truck beds and rail cars

- Helps protect against corrosion and increases lubricity

Other notable points include:

- Proven to work on metal, wood or rubber composites

- Is completely non-hazardous and non-toxic, perfect for use in confined areas, underground and in environmentally sensitive locations

- Has no recorded negative effect on equipment or processing circuits

- No dilution is required – our products are delivered ready to use

- Applicator systems, both hand-held and fully automated, are available for any application

All contents © Copyright Global Barrier Services, Inc. 2016-2024.

All Rights Reserved.